The blades should be designed so that the generator of the turbine rotates at the optimum speed at the desired range of wind speeds. The blades also affect the cut-in and cut-out wind speed of the turbines. The operation noise and vibration are also affected.

The parameters of the blades include shape, size, length, pitch, profile, material, weight, rigidity, number, etc.

Blades should be large in size, long in length, large in pitch and more in number at low wind speed.

The length of the blades can be modified to ones slightly larger for sites with low wind speeds or to ones slightly smaller for sites with high wind speeds.

Angle of Attack

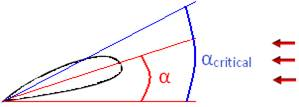

The amount of surface area available for the incoming wind is key to increasing aerodynamic forces on the rotor blades. The angle at which the blade is adjusted is referred to as the angle of attack, α. This angle is measured with respect to the incoming wind direction and the chord line of the blade. There is also a critical angle of attack, αcritical, where air no longer streams smoothly over the blade’s upper surface. Figure 2 shows the critical angle of attack with respect to the blade.

|

|

| The Critical Angle of Attack (αcritical) with Respect to the Blade |

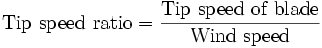

Tip Speed Ratio

The tip speed ratio λ (lambda) or TSR for wind turbines is the ratio between the rotational speed of the tip of a blade and the actual velocity of the wind.

This is an important parameter to evaluate the performance of a wind turbine. The tip speed of blade refers to the speed of rotation of the turbine. The higher the rotation speed of the turbine, the higher the output power of the turbine. Therefore if the TSR of a particular turbine is high, the efficiency will be higher.

Power Control Methods

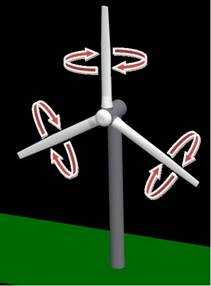

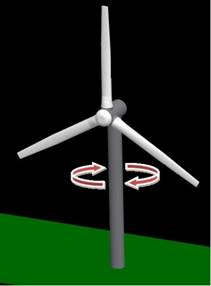

The power output of the turbine can be optimized at the rated operating wind speed or limited at wind speed above the cut-out wind speed. The generator speed, blade angle adjustment, and rotation of the entire wind turbine can be controlled. Blade angle adjustment and turbine rotation are also known as pitch and yaw control, respectively. A visual representation of pitch and yaw adjustment is shown below:

|

|

|

| Pitch Adjustment | Yaw Adjustment |

The purpose of pitch control is to maintain the optimum blade angle to achieve certain rotor speeds or power output. Stall and furl are two methods of pitch controls. By stalling a wind turbine, increasing the angle of attack, causes the flat side of the blade to face further into the wind. Furling decreases the angle of attack, causing the edge of the blade to face the oncoming wind. Pitch angle adjustment is the most effective way to limit output power by changing aerodynamic force on the blade at high wind speeds.

Yaw refers to the rotation of the entire wind turbine in the horizontal axis. Yaw control ensures that the turbine is constantly facing into the wind to maximize the effective rotor area and, as a result, power. Because wind direction can vary quickly, the turbine may misalign with the oncoming wind and cause power output losses.